First, the 【electric push rod blind valve】 Product Overview

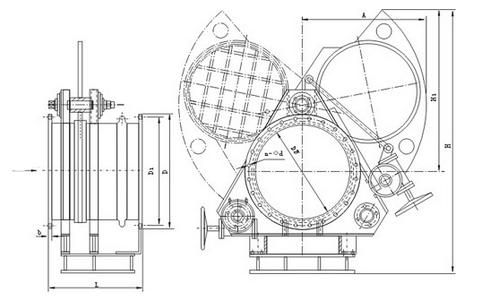

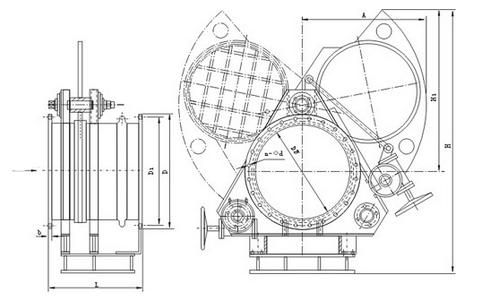

Electric

push rod fan blind valve, also known as electric push rod fan glasses

valve, electric push rod fan flap, mainly by the left valve body, the

right valve body, stem, gate , Seals, electric putter and other

components, and by the base, the support column to form a rigid

structure. Sealing parts with stainless steel and rubber seals, good

sealing performance, long service life, set the seal on the gate, easy

to replace the seal when the seal, rubber seals set in the

gate. Electric push rod blind valve can be a single long-distance

control, remote control can also be more than one network, under normal

circumstances can also use the valve itself device manual operation.

Second, 【electric push rod blind valve】 Product Features

1, the valve in the switching process, the door seals no wear and tear, sealing performance and easy to replace the seal.

2,

The transmission uses the principle of the connecting rod mechanism,

the structure is simple and suitable for the harsh environment of the

work place, the transmission stroke is accurate and the clamping force

of the clamping mechanism at the three clamping points is even.

3,

taking into account the structural characteristics of the blind valve,

blind valve seal at the weaknesses of two rigid strengthening treatment,

the sealing performance more reliable.

4, electric push rod

positioning using a new type of inductive electrical appliances,

reducing the sender may produce unnecessary sparks, the use of safer.

5,

due to gas flow, easy to valve stainless steel telescopic bellows

erosion phenomena, the valve design in the pipeline chamber bellows

diversion sleeve with good wear resistance 16Mn steel while increasing

its thickness.

6, sealing ring material selection of high temperature resistant and gas-resistant fluorine rubber.

Third, [electric push rod blind valve] scope of application

F9T43X

electric push rod blind valve is based on GB6222 "industrial gas safety

regulations," the relevant standards while digesting and absorbing

advanced technology at home and abroad, based on their own research and

development of a new generation of products, mainly used in various

industrial and mining enterprises, environmental protection and other

industries Gas, air, flue gas and other gas pipeline media, as cut off

all kinds of toxic, harmful and reliable device.

Fourth, [electric push rod blind valve] working principle

First

electric clamping push rod through the motor-driven, the thrust through

the crank directly on the active clamping screw stem to rotate and make

the three threaded stem through the link mechanism to do synchronous

rotation, driven by the respective left and right valve Lever nut so

that the left valve body and the valve body in the same time compressing

the bellows to the valve plate as the center of the relative movement

so that the door gasket completely from the two body seals. Re-start the

electric push rod thrust will be the door blind ring and through-ring

replacement, electric clamping push rod action again, will clamp the

door rubber seal, so as to achieve the valve seal. The door is composed

of a blind plate and a through ring. When the tightening mechanism is

released, the door can rotate and change positions to realize the valve

switch.

Fifth, [electric push rod blind valve] technical parameters

|

Nominal pressure PN (MPa)

|

0.25

|

0.15

|

0.10

|

0.05

|

|

Seal test pressure (MPa)

|

0.275

|

0.165

|

0.11

|

0.055

|

|

Strength test pressure (MPa)

|

0.375

|

0.225

|

0.15

|

0.075

|

|

Drive source

|

Electric device

|

|

Applicable temperature (℃)

|

Nitrile rubber

|

Silicone Rubber

|

fluororubber

|

|

-20-100

|

-20-200

|

-20-300

|

|

Suitable media

|

Gas and other toxic and harmful gases

|

|

Opening and closing time (S)

|

≤ 60

|

|

The main components of the material

|

Valve

body, the gate for the carbon steel; screw for the alloy steel; nut

manganese copper alloy, ductile iron; expansion device for stainless

steel

|

Six, [electric push rod blind valve] size specifications

|

DN (mm)

|

Overall dimensions (mm)

|

|

D

|

D1

|

b

|

n-φd

|

L

|

|

300

|

440

|

395

|

18

|

12-φ22

|

500

|

|

350

|

490

|

445

|

18

|

12-φ22

|

600

|

|

400

|

540

|

495

|

24

|

16-φ22

|

600

|

|

450

|

595

|

550

|

24

|

16-φ22

|

600

|

|

500

|

645

|

600

|

26

|

20-φ22

|

600

|

|

600

|

755

|

705

|

26

|

20-φ26

|

600

|

|

700

|

860

|

810

|

26

|

24-φ26

|

600

|

|

800

|

975

|

920

|

35

|

24-φ30

|

800

|

|

900

|

1075

|

1020

|

35

|

24-φ30

|

800

|

|

1000

|

1175

|

1120

|

35

|

28-φ30

|

800

|

|

1100

|

1275

|

1220

|

35

|

36-φ30

|

800

|

|

1200

|

1375

|

1320

|

35

|

32-φ30

|

800

|

|

1300

|

1475

|

1420

|

35

|

36-φ30

|

800

|

|

1400

|

1575

|

1520

|

35

|

36-φ30

|

800

|

|

1500

|

1675

|

1620

|

35

|

36-φ30

|

850

|

|

1600

|

1790

|

1730

|

35

|

40-φ30

|

850

|

|

1800

|

1990

|

1930

|

35

|

44-φ30

|

1100

|

|

2000

|

2190

|

2130

|

35

|

46-φ30

|

1100

|