[Basic Information]

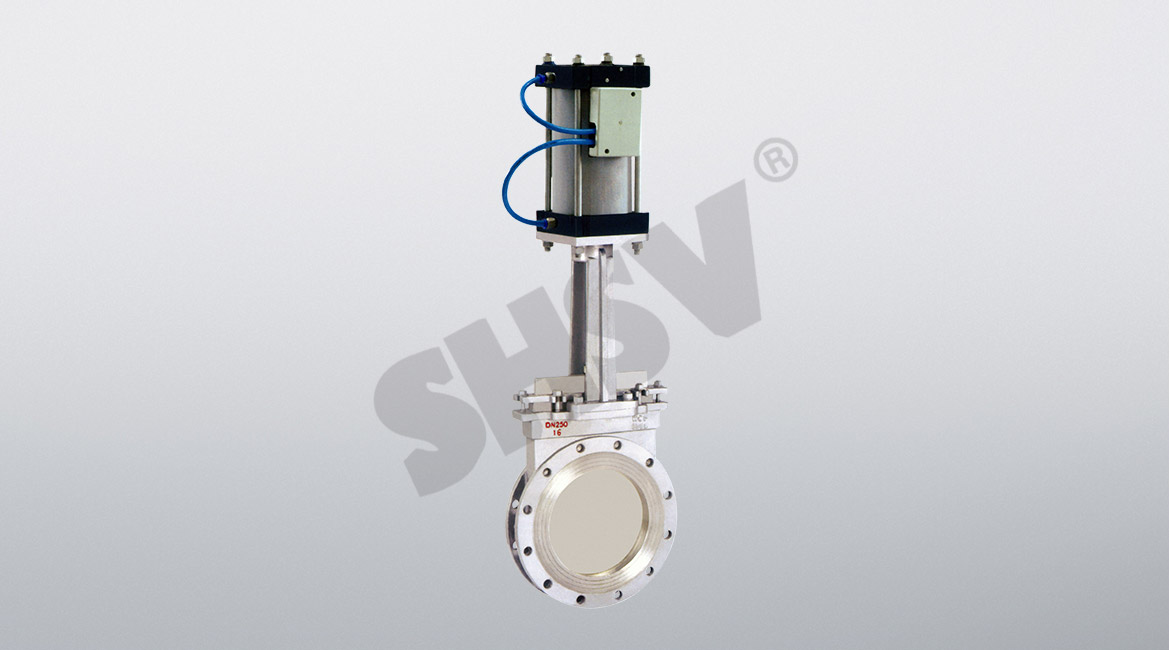

Pneumatic knife gate valve is

one of the important varieties of the production process control

valve. Equipped with a solenoid valve to complete the switch control,

with electrical valve positioner can also be completed to adjust the

control. Users can match the actual needs. The main cast steel,

stainless steel and so on. It is particularly suitable for the paper

industry, chemical industry, coal, sewage, sugar and other industries.

|

Connection method

|

On the folder, lugs

|

|

Cylinder form

|

Double role

|

|

control method

|

Switch type, adjustable type

|

|

Air pressure

|

Double role: 4 ~ 8bar, single role: 5 ~ 8bar

|

|

Medium temperature

|

W1: -40 to 180 W2: -40 to 180 W3: -30 to 425 W4: -40 to 425

|

[Valve Features]

1, the overall design of the valve, fluid resistance, flexible and convenient operation.

2, manual knife gate valve screw drive with double plane bearing

design, making the transmission friction greatly reduced, so the valve

open light and smooth.

3, the knife valve seal seat with a movable seal, and the use of

O-ring preload to provide pre-tightening the seal seat close to the

valve, the amount of leakage greatly reduced on the long-term use of

seal wear automatic compensation function to improve The service life.

4, fixed guide claws, no groove design, not easy to cause media accumulation or jamming.

5, The valve seat can choose metal hard seal or soft seal

according to the requirement of medium and working conditions: The gate

adopts the chrome plating or ion nitriding on the surface to make the

gate more wear-resistant and the service life of the sealing surface is

longer; the soft sealing is optional PTFE seat or reinforced PTFE seat

or EPDM, NBR, good sealing, corrosion-resistant.

6, the media to adapt to a wide range: good sealing performance

and economic practicality, operation can be manual, pneumatic, electric,

practical range is very wide.

[Adaptations]

Knife-type

pneumatic gate valve is an important industrial automation and control

system executive body, remote control can be centralized to meet the

needs of computer-controlled; now in the petrochemical industry, gas

equipment, nuclear industry, power equipment, environmental water

treatment, HVAC, steel Metallurgy, industrial furnaces, canning

equipment, brewing equipment, drying equipment, vacuum equipment,

surface treatment, biopharmaceuticals, food machinery, textile printing

and dyeing, papermaking and other industries are widely used, but also

the national defense construction, construction of science and

technology of choice.

[Main shape and connection size]

|

MPa

|

DN

|

L

|

D1

|

D2

|

H

|

nM

|

MPa

|

DN

|

L

|

D1

|

D2

|

H

|

nM

|

|

0.6 MPa

|

50

|

48

|

90

|

110

|

335

|

4-M12

|

1.0 MPa

|

50

|

48

|

100

|

125

|

335

|

4-M16

|

|

65

|

48

|

110

|

130

|

363

|

4-M12

|

65

|

48

|

120

|

145

|

363

|

4-M16

|

|

80

|

51

|

125

|

150

|

395

|

4-M16

|

80

|

51

|

135

|

160

|

395

|

4-M16

|

|

100

|

51

|

145

|

170

|

465

|

4-M16

|

100

|

51

|

155

|

180

|

465

|

8-M16

|

|

125

|

57

|

175

|

200

|

530

|

8-M16

|

125

|

57

|

185

|

210

|

530

|

8-M16

|

|

150

|

57

|

200

|

225

|

630

|

8-M16

|

150

|

57

|

210

|

240

|

630

|

8-M20

|

|

200

|

70

|

255

|

280

|

750

|

8-M16

|

200

|

70

|

265

|

295

|

750

|

8-M20

|

|

250

|

70

|

310

|

335

|

900

|

12-M16

|

250

|

70

|

320

|

350

|

900

|

12-M20

|

|

300

|

76

|

362

|

395

|

1120

|

12-M20

|

300

|

76

|

368

|

400

|

1120

|

12-M20

|

|

350

|

76

|

412

|

445

|

1260

|

12-M20

|

350

|

76

|

428

|

460

|

1260

|

16-M20

|

|

400

|

89

|

462

|

495

|

1450

|

16-M20

|

400

|

89

|

482

|

515

|

1450

|

16-M22

|

|

450

|

89

|

518

|

550

|

1600

|

16-M20

|

450

|

89

|

532

|

565

|

1600

|

20-M22

|

|

500

|

114

|

568

|

600

|

1800

|

16-M20

|

500

|

114

|

585

|

620

|

1800

|

20-M22

|

|

600

|

114

|

670

|

705

|

2300

|

20-M22

|

600

|

114

|

685

|

725

|

2300

|

20-M27

|

|

700

|

127

|

775

|

810

|

2500

|

24-M22

|

700

|

127

|

800

|

840

|

2500

|

24-M27

|

|

800

|

127

|

880

|

920

|

2800

|

24-M27

|

800

|

127

|

898

|

950

|

2800

|

24-M30

|

|

900

|

154

|

980

|

1020

|

3100

|

27-M27

|

900

|

154

|

1005

|

1050

|

3100

|

28-M30

|

|

1000

|

165

|

1080

|

1120

|

3400

|

28-M27

|

1000

|

165

|

1115

|

1160

|

3400

|

28-M30

|

|

1200

|

190

|

1295

|

1340

|

3600

|

32-M30

|

1200

|

180

|

1325

|

1380

|

3600

|

32-M36

|